Quality - The Necessary Key to Made in America

American manufacturing is cost effective, if you care about quality.

-

Tools:

by Friendly Bear

Once upon a time, mighty beasts roamed the Earth. These mighty beasts were powered by V8 engines and they bore names like Chevrolet, Ford, Plymouth, and Pontiac. They were symbols of America. Surely a nation must be great, whose proud workers bring forth such creations.

Yet, at that same time, other American workers were churning out hammers, drills, screwdrivers, locks, lamps, fans, blenders, fire extinguishers, blankets, furniture, socks, pocketknives, baby bottles, shoehorns, and every other product that improves our lives.

The secret was not that they were the cheapest products, but that they were well-made and affordable by everyday people. The products fulfilled their promise and lasted long. In a word, quality.

This morning, my house had its annual termite inspection. The inspector was a positive, very likable person, who genuinely meant well. In a speedy 8 minutes, the inspector, whom I’ll call W for Well-intentioned, checked the exterior of my house, the garage, and the basement. While I am certainly not a professional termite inspector, I have had enough exposure to the little nightmares to know that W’s inspection was woefully inadequate.

When I gently prodded W to examine a corner closest to the soil, he pressed his fingers against the siding and declared the corner solid and free of termites. I didn’t have the heart to tell him that the siding was Hardiplank, a fiber-reinforced cement siding. Pressing the siding as he did gave little indication of the structure behind.

The garage and basement inspections also were sad. W had been issued a dim flashlight. We’re talking kiddy-light dim - like, the flashlights in a fictional TV crime drama dim.

I don’t blame W. He had a great attitude. I blame his boss and his boss’s boss. No one took the time or effort to properly train and equip W. No one took the time or effort to insure quality.

Meanwhile, a few miles away in a store, quality was shining brightly. One night, I stepped in to shop for a new microwave, mine having quit working after 18 impressive years of warming up various bits lurking in the refrigerator and old pizza scraps.

Two aisles before choosing a new, electromagnetic best friend, I came to the stoves. They were beautifully finished. Their seams were consistent and flawless. Their knobs didn’t rattle, and they smoothly turned into each setting without wiggle. I was impressed. So impressed was I, that I spent more than 20 minutes admiring them.

Though they had been made by different companies, they each bore a decal that momentarily mesmerized me. It read, “Made in America”. They were well-made in America!

By 1975, Americans were increasingly seeing imported products, the quality of which varied from the exceptional to the “Why did I waste my money?”.

But, by the early 1990’s, cheap imported clothes, tools, jewelry, shoes, appliances, wristwatches, and pretty much everything else, was flooding in from China.

The explanation so frequently given by CEOs, elected officials, and “talking heads” on financially-focused TV shows, was, “It would cost too much to make it in America.”, or “The cost of labor is just too high.” Maybe paying American workers who take pride in their work, instead of outsourcing to a slave labor factory, would result in a better product and hardcore brand loyalty?

Perhaps “Made in America” doesn’t leave enough profit for someone’s liking, but it can be made here! And, as a consumer, I feel pride when I buy a great product that’s made in America. I’m sorry if that sounds hokey or corny to you, because it’s true.

Made in America got a big boost from innovations such as metal injection molding replacing time-consuming machining, sonic welding and better adhesives replacing fragile fasteners, and computer software that accounted for tool wear. Whereas technology and advancements in manufacturing had once replaced American workers, now they made jobs for Americans possible. Even better, they gave American workers the implements to bring forth highly desirable products at prices many could justify.

You can never “out cheap” China, so don’t even bother trying. But, you can “out quality” them!

Though some people may find the prices of German luxury cars, Swiss wristwatches, premium Japanese cameras, or silk Persian rugs, outside of their comfort zones, there is usually great admiration for the quality of manufacture. American workers are once again proving that they can match anyone’s fit and finish at prices that fit most budgets.

Need proof? My refrigerator is proof! It was made in America, and 20 years later it’s still running. My need to go on a diet is proof that I’ve opened my refrigerator’s doors way too often. Yet, it still hums along. My old washer and old dryer, both American made, lasted 32 years! Build a solid, dependable product and you build brand loyalty.

What, might you ask, brought about this “coming home” of manufacturing? A President who believed in American workers and put forth the effort to make it happen.

Best of all, the effort wasn’t wasted; American workers are making the most of the opportunity. And that, my friends, is reason to feel positive.

-

Tools:

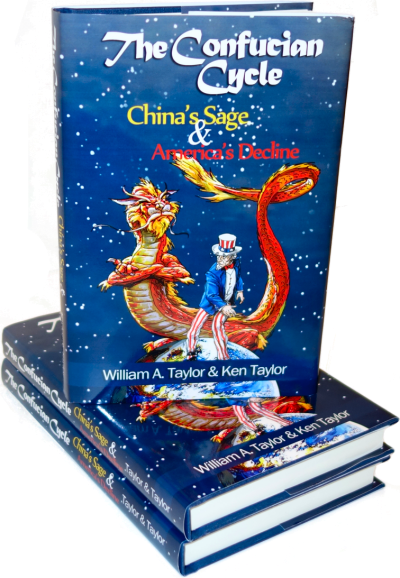

What does Chinese history have to teach America that Joe Biden doesn't know?

i, too, buy american whenever possible, and have usually had the same good luck U had with your old washing machine and dryer. sometimes, however, the same stupid management attitude that caused the manufacture of washing machines and dryers (and lots of other stuff) to be moved to china in the first place causes managers to coast on the reputation of their brand rather than producing quality products. at one time, i owned a dryer, an oven, a dishwasher, and a refrigerator all made by the same appliance manufacturer, and every single one of the devices had failed - after repeated attempts at repair by manufacturer representatives - before they were 5 years old. i accept that statistically speaking, it is *ALWAYS* possible to buy a lemon, because *NO* manufacturing process is perfect, nor is even a single person participating in that process, so bad products *will* get through. the manufacturer, however, was rude and unhelpful in every case (not the people they sent, however; like W, they were polite and really tried to fix things), so i stopped buying the *ALL* of the manufacturer's products. customer care is *EXTREMELY* important; i would say it is as important - if not more so - as overall product quality.

fortunately, management changes over time, so it is always possible that its practices will improve; i have seen this recovery happen with retail establishments over my lifetime. nevertheless, i still avoid the manufacturer of those failed products, and will likely do so for the rest of my life (i'm an old fart). i have also told others about my experience with that company, so it might behoove managers at companies to pay attention to *customers* rather than just to the bottom line; that, like employing one's neighbors here in the u.s. creating quality products rather than outsourcing to slave labor camps, is more likely to create both happy customers *and* a healthy bottom line.

Well, as a retailer or manufacturer, it's possible to wear your pride in quality straight to bankruptcy court. Increasingly, today's customers, especially the younger ones, make choices based on different criteria than did customers in the past. In the dark ages, you simply bought the best quality you could afford. Today, thanks to many factors, especially the internet, image trumps quality!

That $25 Gucci knockoff bag really does the trick on Facebook, except, of course, that anyone who knows you at all knows that you couldn't afford the real thing in a million years! This leads to another topic, for another day: the cultivation of delusional narcissism in sales.

I remember the amusement generated by the 1976 Ford ad for the new Granada sedan; "Looks just like a Mercedes".

I think that may have been the beginning.....