The Government-Assisted Productivity Scam

Most of the recent "productivity increases" are phony accounting.

-

Tools:

From right after World War II until the mid-sixties, American manufacturing firms ruled the world. There were no Japanese cars on American roads and very few foreign cars of any kind until the late 1960's.

A major reason our firms did so well was that foreign competitors such as the French, Germans, and the Japanese had had their industrial plant bombed flat during the war. We had essentially no competition as they rebuilt their infrastructure from scratch.

Demand for manufactured goods had built up during the war when most factories were making armaments. When factories converted to civilian production at the end of the war, there was so much demand that sales were production-limited. Businesses could sell just about anything they could make, as fast as they could crank it out.

Over time, of course, as competitors rebuilt their factories and demand began to be satisfied, it became more difficult to sell just anything, a product had to offer something new. This happened to telephones, radios, cars, eventually TVs, PCs, cellphones, and a host of other innovations which sold like crazy for a while and then saturated their markets.

Once saturation occurs, sales are limited by marketing's ability to persuade customers to discard perfectly good items and get new ones. It's harder to sell a car to someone who already has a car than to sell to someone who doesn't have a car at all.

The Post-Industrial Society

As American manufacturing lost worldwide market share, we were told that it was OK for the US to become a "post-industrial economy." We wouldn't have to work in factories any more, we'd all become "knowledge workers" in the "service economy."

While we at Scragged are not licensed economists, we felt a certain skepticism towards this claim that we don't need manufacturing to prosper: How can everyone make a living taking in each other's laundry?

When the New York Times recently explained the assumptions behind some rather important government productivity data, light dawned and we figured out what's been going on.

We've been told for years that the productivity gains that accompany deregulation and innovation more than make up for short-term unemployment as jobs are eliminated.

Given that most markets are saturated and that sales are limited by people's willingness to discard perfectly good products for new ones, increased productivity inevitably leads to job loss - the fewer people it takes to make, say, iPods, the fewer jobs there are in the iPod plant. Sales aren't going up - everybody who wants an iPod has one and they don't wear out very fast, so productivity improvements come directly out of jobs.

Apple itself is an exception to this rule because it designs brand-new products often enough to keep sales humming along. There aren't too many laid-off workers at the iPod factory because they're now making iPads, the one changed letter making all the difference. Unfortunately for job seekers, very few businesses are able to innovate fast enough to keep employment steady.

The Times pointed out that in the early 1980's, wages no longer increased as productivity increased. Until then, wages had gone up as businesses and workers split the gains from productivity increases.

Apologists for stagnating wages claimed that workers weren't learning new skills as their jobs moved overseas, but we now know the real reason wages stagnated - government productivity data are bogus.

The Productivity Puzzle

Productivity is based on the number of hours of labor needed to make something such as a car, a TV, or a PC. As businesses adopt new processes that reduce the amount of labor needed, productivity goes up, profits go up, output per worker goes up, and they can afford to pay their workers more. We didn't understand why wage growth stopped in the 1980's as productivity kept rising.

The problem is that our government, in its infinite wisdom, defines productivity based on the number of hours of American labor. This was OK as long as manufacturers bought from American suppliers, but outsourcing to China threw the data off.

Suppose it takes 100 hours of labor to make a car. The manufacturer decides to buy low-tech items such as seats and interior trim from China. Making those would take, say, 10 hours of labor in the US, but by switching to a Chinese source, making seats and trim now takes zero American labor-hours.

Instead of 100 hours to make a car, the government sees only 90 hours. From the government's point of view, productivity has gone up by 10%.

In actual fact, the only reason to outsource seats is that the Chinese sell them cheaper than the auto company can make them. Given that Chinese labor is a lot cheaper than American labor, the Chinese vendor probably doesn't use much automation.

Since the seats are now made more or less by hand, labor hours went up instead of down. Outsourcing the seats to China reduced productivity in that it now takes more labor hours to make the car, but US productivity went up as far as government is concerned.

Based on such bogus data, economists have argued that outsourcing improves productivity and thus benefits American living standards. We now know why this didn't happen - every hour of the "increased" productivity came out of US hours worked.

This lowered total worker income and reduced living standards. As the Times put it:

In 2009, the data show, Americans needed 40 percent fewer hours to produce the same unit of output as in 1980.

Although there may have been some real productivity gains here and there as processes improved, we now know that what really happened is that 40% of manufacturing labor moved overseas via outsourcing.

All the income taxes paid by the offshore workers went to the governments of India and China instead of to the government of the United States. Their salaries were spent in India and in China and drove economic activity there instead of in the United States.

There wasn't much that the displaced American workers could do to retrain themselves for new jobs because bogus productivity increases didn't create any new jobs. Although the cost savings from outsourcing seem large, dividing by the number of remaining employees shows that there wasn't much money available for raises. Only real increases in productivity can support raises; bogus productivity doesn't cut it.

It's nice to think of millions of Chinese peasants moving out of the rice paddies into the middle class; it's not clear that the cost in terms of lost American jobs is worth whatever cost reductions management achieved by outsourcing.

Real Productivity Still Counts

Just because the highly-hyped productivity increases over the last couple decades are largely bogus doesn't mean that we shouldn't do all we can to maximize real productivity. The Detroit News, which has followed the automobile business closely for nearly a century, sent a camera crew to film a modern Ford assembly plant in Brazil. Even though Brazilian labor costs far less than American labor, this plant has more automation than the most modern American plants.

Why not just hire more cheap workers for pennies? Automation doesn't just save labor, it also increases quality: robots are far more consistent with respect to quality because they don't get tired. Most automation used in mass-production situations would be worthwhile even if humans cost nothing because machines do a better job and can work 20 hours per day.

In addition to using maximum automation, Ford encouraged their suppliers to set up production lines on the same site to minimize shipping costs and delays. This reinvents Henry Ford's original River Rouge complex where everything happened in one place. Iron ore came in one end and cars rolled out the other.

As Toyota has argued for decades, integrated just-in-time manufacturing on the same site maximizes productivity. American manufacturers couldn't readily do this because very few of their plants had space for suppliers to set up, but they can design brand-new sites to maximize just-in-time. What's more, since all the labor occurs in one place in that sort of setup, labor costs including outsourced parts are captured so productivity data are real.

As far as the Detroit News can tell, the Brazilian plant they examined is the most truly efficient automobile assembly system in the world. It's probably productive enough to overcome the cost advantages of buying parts from China when shipping costs and the extra inventory needed to buffer against delivery delays are included. Toyota and other foreign manufacturers have put up plants which include space for suppliers all over the American south so this system is known to work in America.

Why, then, don't Ford and GM use this technique in America? Because the United Auto Workers are implacably opposed to "supplier integration" - they insist on owning all the jobs in any Ford or GM facility. The Detroit News doubts that American manufacturers will ever build a new assembly plant in the US - they'll do it overseas and import as much labor as they can in the form of entire cars or major assemblies. While this may make productivity look really high - it takes very little labor to assemble a car if all you have to do is snap together a few subassemblies - there won't be many UAW jobs left to protect.

Is Globalization Good?

We've seen how bogus productivity data were used to justify not being concerned about jobs lost due to outsourcing and other forms of globalization. The fact that our government published misleading productivity figures has made it difficult to make sound decisions about how to conduct businesses.

Outsourcing makes profits look good in the short term, of course. Some time back, IBM moved a software development project to India. Instead of costing $1 billion, they could get the software for about a half-billion, a roughly 50% saving. This added a half-billion to IBM's bottom line over a couple of years.

This extra profit came at a cost, however. Most of the cost of software development goes for salaries. By moving a half-billion worth of salaries to India, IBM moved $1 billion worth of salaries out of the United States.

Many of IBM's biggest customers are American businesses who buy IBM products and services so that they can serve their customers. What happens to IBM's customers when aggregate American salaries go down by $1 billion? What happens to IBM when their customers lose the business they'd get from $1 billion worth of salaries paid to American workers?

When a big enough firm ships enough work overseas, they hurt their own customers enough to make a difference. How many Wal-Mart customers lose their jobs and can't afford to shop there any more as Wal-Mart buys more and more products from China?

Basing economic policy on false data leads to disaster. Now that we know that our productivity figures have been faked for decades, what should we do about globalization?

Mr. Obama is talking about encouraging American factories and is talking about promoting exports. This is the usual glib, obvious-seeming answer to creating more high-productivity, high-paying jobs, but there are fundamental obstacles to getting American businesses to manufacture in the United States.

To name but one roadblock, our labor unions have enough political clout to persuade the Obama administration to adjust policies on the National Labor Relations Board to make it easier to unionize factories, and unionization forces capital-intensive manufacturing firms into bankruptcy over time. Given the institutional obstacles facing American manufacturers, what can we do about globalization?

-

Tools:

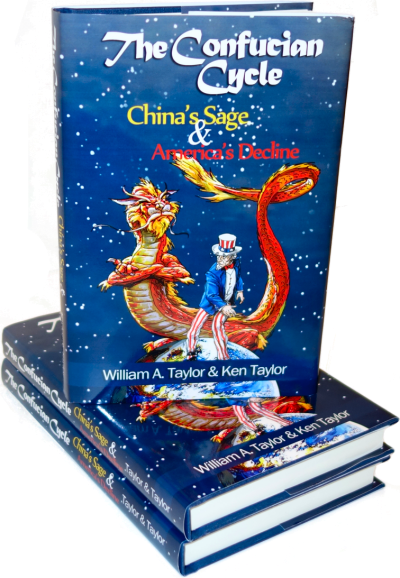

What does Chinese history have to teach America that Mr. Trump's cabinet doesn't know?

All economic units, from Continents to towns must on average export as much value as they import. This value can be in any form, including services, such as call centers in India. India is exporting a service, bringing value into India. A game like World of WarCraft brings huge sums of money into America from overseas. Although Blizzard is owned by a French company so I'm not sure if that money stays in the states. That does, however, show how while it is vital for an area to export something it does not have to be something tangible like a car.

Looks like schizophrenia to me.